Birth and evolution of the cork stopper

Apr 22, 2022

1 comment

Cork is the most used raw material, especially in Italy, for the production of wine corks.

The cork oak, also called cork oak, is a tree with a straight and often sinuous trunk, whose height can reach 15-20 meters.

It is a long-lived plant, typically Mediterranean, present in the Iberian region, in France, Italy and in northern Africa. In Italy it is mainly present in the major islands, on the Tyrrhenian coasts and in Puglia. It is a plant that prefers a climate with moderate rainfall, cool soils and a temperature between 13 ° and 14 °. It has an evergreen foliage, the circumference of the trunk can reach three meters and if it is not exploited for the production of cork, it can live up to 300 years. To recover the large strips of cork on the plants, decortica is practiced, which is an ancient technique characterized by many rules.

Harvesting takes place from mid-May to the end of August, but for the first barking the trees must be between 25 and 30 years of age. The product of the first extraction, rigid and irregular, is called "male cork" and cannot be used to produce corks. Nine years later, the second de-tapping will take place, but the extracted cork of “first reproduction” does not yet have the right quality to be used to make corks. Another nine years will pass before the third, and from then on, the cork defined as "female" will finally be suitable for the production of corks. In the interval of nine years the oak will have all the time necessary to reform a sufficiently thick bark. specialized (extractors) must cut the plant vertically along the trunk, and horizontally under the main branches with great skill, so that the hatchets do not cut the sap-carrying vessels essential to feed the tree. they will have to detach the cork from the layer below that protects the woody core that generates the bark. The exploited cork can live up to 150 years.

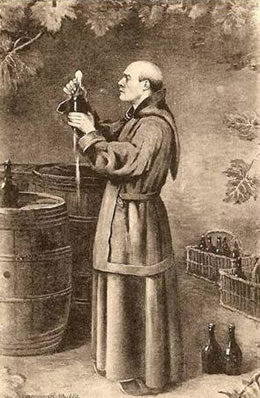

Traces of the first rudimentary corks date back to the ancient Greeks (5th century BC) who used them for closing jars and jars. It was Pierre Dom Perignon, a famous Benedictine monk who lived in the north of France in Abbey of Saint-Pierre d'Hautvillers between 1600 and 1700, to invent the "real" corks, using them to imprison the gas of the sparkling wine he produced. He noticed and took inspired by travelers and, above all, by pilgrims from Spain, who closed their leather bags and dried pumpkins with cylinders of cork; a technique in turn copied to the Iberian peasants who lived near the cork oak forests. Before the hour, the closures adopted were composed of pieces of wood soaked in pitch or resin, but the product of the refermentation came out easily.

Over the course of history, the production of one-piece natural cork has undergone a major transformation; was in fact found the remedy ad one of the greatest and feared among the problems that many of the most important and precious wines presented, that is the high margin of risk in conservation better known as the "scent of cork". The main cause of this problem that gave wine an unpleasant smell / taste of mold, is Armillaria Mellea, a parasitic fungus that can develop in cork oak, releasing 2/4/6 Trichloroanisole (TCA) in the presence of Chlorine. One gram of TCA can pollute 10 million liters of wine. This molecule is not the only one to give rise to the annoying smell, but it can also be some bacteria and other types of fungi which, in favorable environmental conditions, produce the scent attributable to that of the so-called wet dog, moldy newspaper and damp cellar. .

Some recent studies have established that TCA (produced by secondary metabolism) does not have its own smell but prevents our olfactory system from feeling the true aromas of wine which react with an unpleasant false perception. Its formation does not only affect closed bottles with contaminated lots of caps but, even more seriously, the cellars where chlorine-based products are usually used for the treatment of wood and utensils. Specialized companies have developed a high-precision instrument with vocus screening technology (molecular scanning) that ensures the absence of TCA in single-piece natural caps. Over the years, cork has been the most used material par excellence for all those white, red and complex wines for aging, which require micro-oxygenation for their evolution in the bottle.

The process for the production of corks is essentially divided into 3 important parts: at first the cork must be selected, subsequently sanitized with hydrogen peroxide, or by steam, or with ozone; and finally die-cut. The cork has many properties; in fact, in addition to being ecological, sustainable, impermeable to liquids, flexible and elastic, it guarantees excellent adherence to the neck of the bottle.

The types of caps that exist today are many. Let's now see the most widespread and used starting from the one-piece natural cork stopper, obtained directly from the cut of the cork board; in order to reduce imperfections on the surface, it is treated with a mixture of powder, cork and glue. This type of cap is used forbottling of fine wines as it is a typology very reliable as highly impermeable to liquid and particularly permeable to gas.

The natural multi-piece is instead composed of one or more glued and pressed cork discs; this type of cork is not suitable for wines that require long aging periods.

Then we have the technical cork, intended for still or sparkling wines, obtained from an agglomerate of shredded cork and glue, or finished with a pearl cork washer.

Intended for still or sparkling wines of medium conservation, we have the spark cork, whose agglomerated body is molded, has two natural cork washers in contact with the wine and is recommended for sparkling wines with a long refermentation in the bottle and has the characteristic mushroom shape with safety cage.

The agglomerated cork is made through the agglomeration of cork granules by-products of the production of natural corks and is generally used for the closure of wines for immediate consumption or with a maximum duration of 12 months.

Finally, the encapsulated cork stopper whose shape recalls a "T" which has a body in natural cork while on the upper part, also called the head, a capsule is glued which can be in wood, PVC, metal, porcelain or glass. It is used for the bottling of liqueurs, spirits and fortified wines, and therefore for types of alcohol that will comeyear opened and closed several times.

Finally, the encapsulated cork stopper whose shape recalls a "T" which has a body in natural cork while on the upper part, also called the head, a capsule is glued which can be in wood, PVC, metal, porcelain or glass. It is used for the bottling of liqueurs, spirits and fortified wines, and therefore for types of alcohol that will comeyear opened and closed several times.

Today, in the wine world, there are many corking solutions for wine developed and used as an alternative to cork on the market; however the cork stopper, with its numerous qualities, remains the system that has had and continues to have the greatest following, and remains firmly anchored at the top of the ranking in the world market.

-----

"The simple act of opening a bottle of wine has brought more happiness to humanity than all governments in world history. Taste is a mystery that finds its best expression in wine."

(Jim Harrison - American poet and writer)

Include a free greeting card by writing your message in the dedicated field at Checkout

Include a free greeting card by writing your message in the dedicated field at Checkout

1 comment

Carlo Giovanni Pietrasanta

Complimenti fatto bene preciso ed esaustivo